...Processing excellence in motion

Applications

- Automotive

- Pigments & dyestuffs

- Chemicals

- Adhesives

- Plastics

- Plastic alloys

- Wood plastic composites WPC

- Mineral Composites

- Highly filled polymer compound

- Plastic/pigment masterbatches

- NANO composites

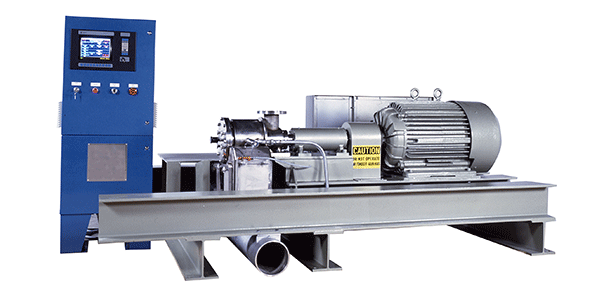

DUSATEC Ultrahigh-Speed Thermokinetic Processing Technology

- Optimum mixing quality in ultrashort time

- Self-cleaning system

- No external heat source required

- Low operating cost

Based on the high-speed thermokinetic principle, the GELIMAT line of high-flow-rate mixer/compounder produces uniformly blended, fully dispersed and, in most cases, fluxed compound that can be immediately processed by a simple shaping device using minimal power. GELIMAT units perform the mixing, dispersing, heating and fluxing so only downstream shaping of the compound is required.

The material processed forms a turbulent centrifugal annular layer of increasing density along the inner wall of the mixing/compounding cylinder. Specially designed mixing elements provide for an extremely high acceleration of the feedstock. Interaction with the braking effect of friction at the walls of the mixing/compounding chamber results in large differences in particle velocity within the annular layer and intensive mixing turbulences. Uniform disintegration and blending of the constituents are thereby achieved in a matter of seconds.

The friction generated by the high differences in velocity within the annular product layers can be used precisely for breaking up agglomerates, drying and melting of polymer mixes.