...Processing excellence in motion

Applications

- Pigments & dyestuffs

- Chemicals

- Adhesives

- Minerals

- Plastics

- Ceramics

- Food

- Chocolates & candy

- Pharmaceuticals

- Cosmetics

- Biotechnology

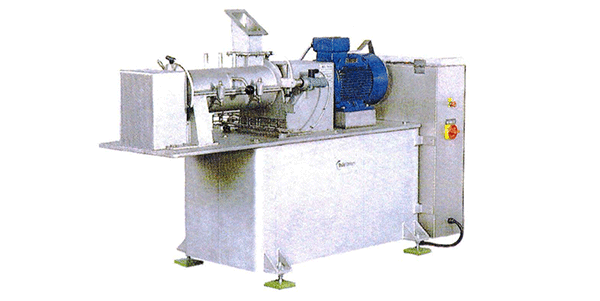

High-Flow Continuous Processing Technology

- Efficient design based on annular forces

- Customizable to feedstock

- Long service life for uninterrupted processing

- Quick to optimize mixing quality

DUSATEC offers a variety of high-flow, continuous processing equipment offering ease of operation and maintenance. Highly customizable and automated, these efficient machines are part of the K-TT and K-TR Tornado systems. Adaptable to the properties of the materials being processed, they offer optimal mixing quality, low energy consumption, long service life and highly customizable features.

The systems are based on the high peripheral speed of the mixing mechanism in which the resultant centrifugal force form a concentric annular layer of the product. The profile of the annular layer features a high mixing intensity, which is caused by the high differential speed between the rotating, specially shaped mixing tools and the mixer wall. The product is moved through the mixing chamber in a plug-like flow, with residence time influenced by the degree of filling, the number of revolutions, the geometry and adjustment of the mixing tools, the mixing vessel length and the volume flow rate.

The system offers the possibility to divide the mixing chamber into zones of different shear intensity, thus permitting system optimization for varying product properties. The liquid components are directly introduced into the annular layer. This ensures a homogeneous distribution within the mixture and avoids wetting of the mixer wall and mixing shaft.

Power input is adjustable to ensure consistent quality especially when fluctuations in feedstock are detected. A variety of mixing tools is available for processing a wide array of materials.